Water Management

Goals and Successes

You can check the table by dragging to right

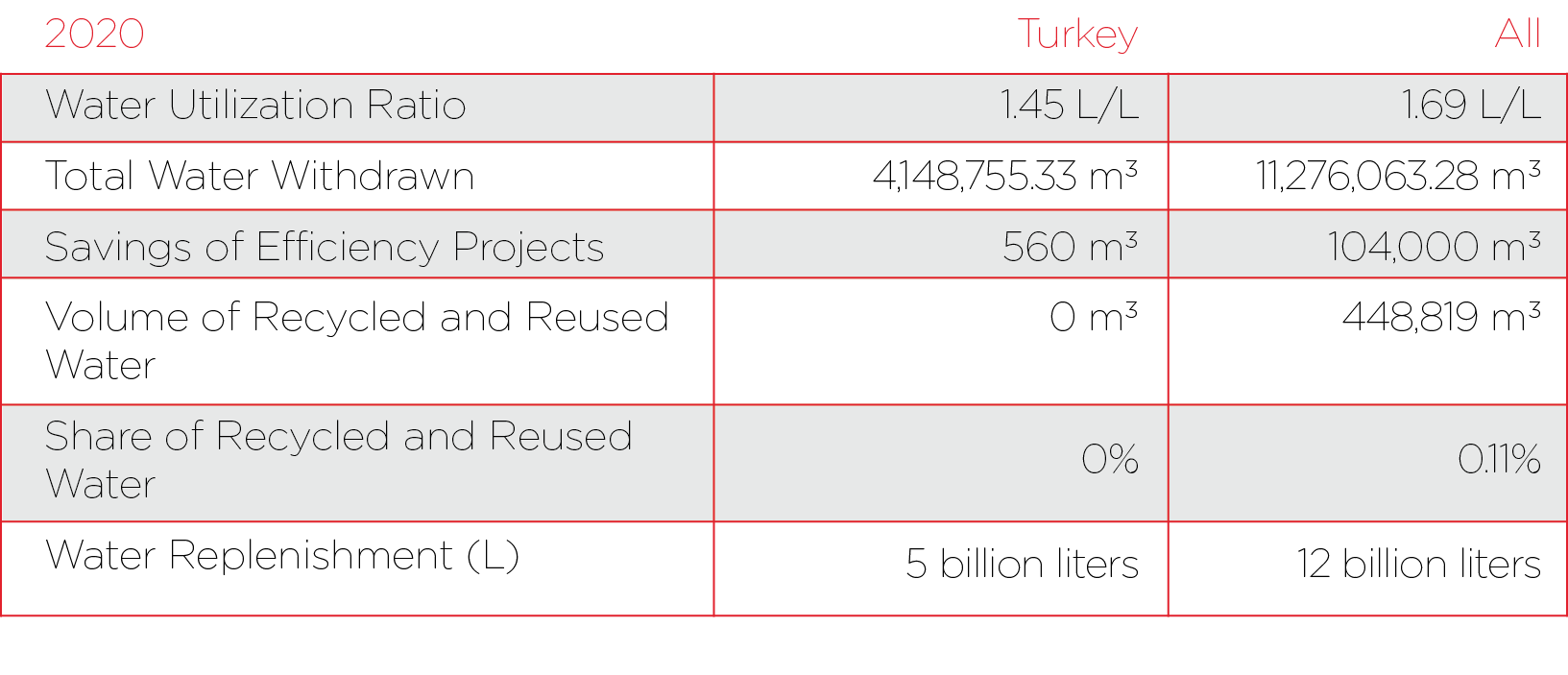

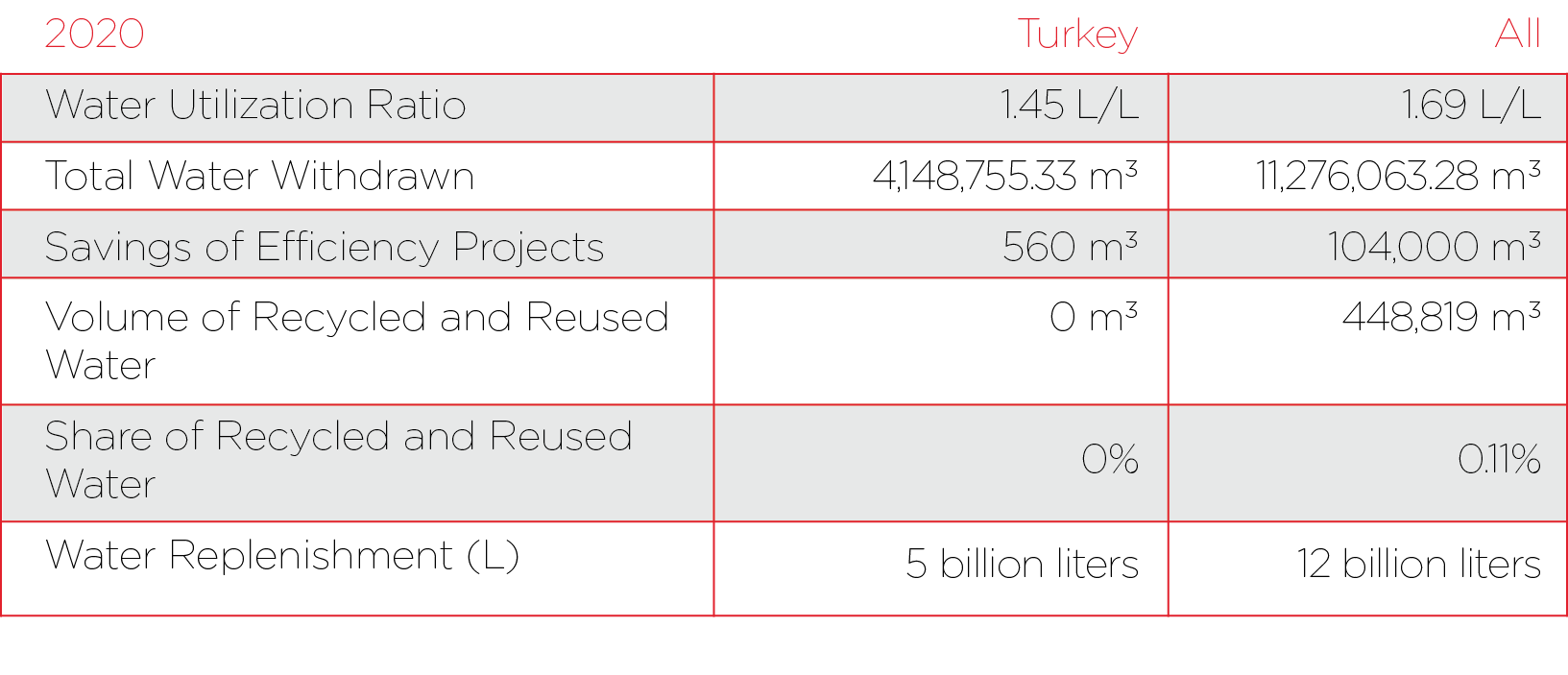

Living standards improve along with developments in technology. However, this development results in an increase in consumption habits. A 40% increase in the demand for water is expected until 2030. One of our most critical natural resources, water is the fundamental content of our products, and an indispensable element of our production. Aware of the impact of the sustainable use of water on the sustainability of our business, we fully support TCCC’s ultimate goal of ‘replenishing every drop of water we use’ with the aim of minimizing our negative impact on water,

which is a high-priority topic for us, and sustaining water-efficient operations. At all of our plants, we consider the impact of the climate crisis on water sources in the basins where our plants are located. On this basis, every year we develop water saving programs in line with the Operational Excellence Culture, make investments, and implement them. In 2020, we saved approximately 104,000 m3 of water in the countries in which we operate.

Our water management strategy is summarized below:

Improving the overall water-use efficiency at our plants;

Implementing Source Vulnerability Assessment (SVA) and Source Water Protection (SWP) studies to protect water catchment basins in the regions where our plants are located;

Managing wastewater and storm water discharge at our plants (achieving 100% compliance in wastewater treatment);

Replenishing the water we use back to nature by implementing locally relevant programs;

Mitigating risk for communities and for our business by partnering with governments, NGOs and communities to assess, understand and generate effective, long-term water

stress solutions and implement source water protection plans;

Researching and investing in new technologies to reduce water consumption;

nvestigating opportunities and conducting feasibility studies to supply sustainable sources.

Water Management Performance

You can check the table by dragging to right

Reductions in Water Usage Ratios (WURs) between 2006 and 2019 (L/L)

.png)

You can check the table by dragging to right

Plant Water Usage and Minimization

At CCI, we monitor the amount of water used for producing one liter of product. Our plants have created water maps in order to follow water consumption on a daily basis. We analyze, evaluate and spread best practices among CCI plants to reduce our water usage ratio (WUR). Our 2021 goal for the CCI Turkey Operation is to achieve a water usage ratio of 1.445 liters of water per liter of product.

.png)

Top 10 Water-Saving Programs

All CCI plants completed the program in 2018, designed to reduce water usage at production facilities and to support the continuous improvement of water usage ratios at our plants.

Some of the top water saving programs included;

Soft water regeneration optimization project at the Isparta plant in Turkey;

Wastewater treatment effluent to be used for road washing at the Lahore plant in Pakistan;

Replacing the water which enters the cooling tower of the PET blow and preform injection parts with reverse osmosis water, and consequently reducing the blowdown amount.

TCCC’s Replenishment Goal

TCCS’s ‘water neutrality’ goal is defined as:

1. Returning the water we use back to the communities we serve by treating all wastewater and returning it to the environment at a level of purity that supports aquatic life.

2. Replenishing the amount of water equivalent to our product volume through locally relevant water and sanitation projects.

TCCS globally replenished an estimated 100% of the equivalent amount of water used in their finished beverages as of 2015. The water replenishment rate for Turkey has reached 139% as of 2020.

Water Replenishment Programs

Since 2005, when it launched its water replenishment programs, TCCC has been working with communities, governments and respected third parties to commission and support projects that address local water needs and safe water access, as well as watershed protection and water for productive use.

These water stewardship programs have been developed considering the following objectives:

to improve safe access to water and sanitation;

to protect watersheds;

to provide water for productive use

to educate and raise awareness about water issues, including engagement on water policy.

Through water replenishment projects, 12 billion liters of water has been recovered to date in our countries of operation covered by the reporting. We will continue replenishment programs in 2021 in local regions through community water projects in line with the results of source water vulnerability assessments (SVAs) conducted for each of our plants.

Source Water Vulnerability Assessment (SVA)

The water we use in our products and our production processes is drawn from local sources. Therefore, as part of our water stewardship program we conduct a local source vulnerability assessment (SVA) and develop a Source Water Protection Plan (SWPP) to use water responsibly, and to mitigate water-related risks to our system and to the communities we serve.

SVAs allow us to assess vulnerabilities to community sources of water and help us determine the potential impact of our water usage and wastewater discharge. This assessment is conducted in five-year rounds at all CCI plants. Our goal for 2020 was identified as conducting SVA studies in our Astana, Çorlu, Izmir, Mersin, Ankara and Baku plants. Accordingly, we conducted SVA studies in our Astana, Çorlu, Izmir, Mersin, Ankara and Baku plants as well as in Ashgabat, thus performing above the identified target.

During the SVA studies that include processes such as field surveys, interviews with plant authorities or site representatives, interviews with local and national authorities, as well as desktop studies, the water basins and sub-basins in the vicinity of our plants are analyzed. This study includes the topographical, geological, hydro- geological and hydrological assessment of the study areas, as well as the identification of any risks to the sustainability of water resources within these areas. As a result of these assessments, we create an inventory of the social, environmental and political risks to the water sources supplying our facilities and the surrounding communities, and evaluate the results of these studies with an SWPP, acting on a plant-by-plant basis.

Wastewater Management

At CCI, in line with our wastewater management approach, which we identified as ‘Zero wastewater generation and reclamation’, in all countries in which we operate we comply with local laws that regulate wastewater purification and discharge. We also have high standards regarding wastewater discharge, and act in accordance with TCCC standards that determine the wastewater pollutant limits for our operations. In many cases, the allowed discharge limits set by TCCC are much lower than the limits established by the local authorities.

In addition to ISO 14001 Environment Management System Audits, all CCI operations are regularly audited in detail by third parties. We monitor our wastewater quality parameters by periodic analyses and reduce our environmental impact by treating wastewater prior to discharge. We also monitor the amount of wastewater discharged per liter of product and develop projects to reduce wastewater generated as a result of our operations.

Water Discharge

In 2020 we discharged 4,420,015 million m3 of wastewater in total in the nine countries in which we operate. We discharged 1,216,272 m3 of this water into the municipal sewer system, 1,778,243 m3 to the organized industrial zone purification plants, and 1,425,500 m3 to ground waters following purification. For TCCC requirements for treated wastewater quality please see Section 6 - Sustainability Performance Indicators. For CCI Plants’ water discharge analysis, please see Section 6 - Supplementary Disclosures for BIST.

A Step Towards a Sustainable Future

CCI Pakistan signed a Memorandum of Understanding (MoU) with the Pakistan Horticulture Agency to supply purified water for cleaning roads and watering green areas.

Foreseeing that we would attain our target, CCI Pakistan signed a Memorandum of Understanding with the Pakistan Horticulture Agency in Lahore (PHA) as a step towards a sustainable future. According to the understanding between the parties, CCI Pakistan shall supply PHA with purified wastewater for the irrigation of green areas and the cleaning of roads for the next five years.

As a compliant and responsible corporate citizen, CCI Pakistan aims at carrying out its share of the responsibility by implementing innovative and effective water utilization mechanisms, and by improving its water utilization ratio. In these critical times, during which Pakistan is suffering from a severe water crisis, CCI Pakistan is leading the way by taking sustainable initiatives that set an example.

.jpg)

.png)

.png)

.png)

%201.png)

.png)

.png)

.png)